BASEPAINT

THE HEALTHIEST PAINT SOLUTION FOR HUMID AREAS!

Mineral wall paint for DAMP spaces

APPLICATIONS Excellent adhesion on moist surfaces

Suitable on stone and concrete, stucco, masonry and plaster (on a cement base)

PRODUCT PROPERTIES Based on mineral resources

Dust free after 30 minutes – paintable after about 2 hours

Available in white and color on request

Mat

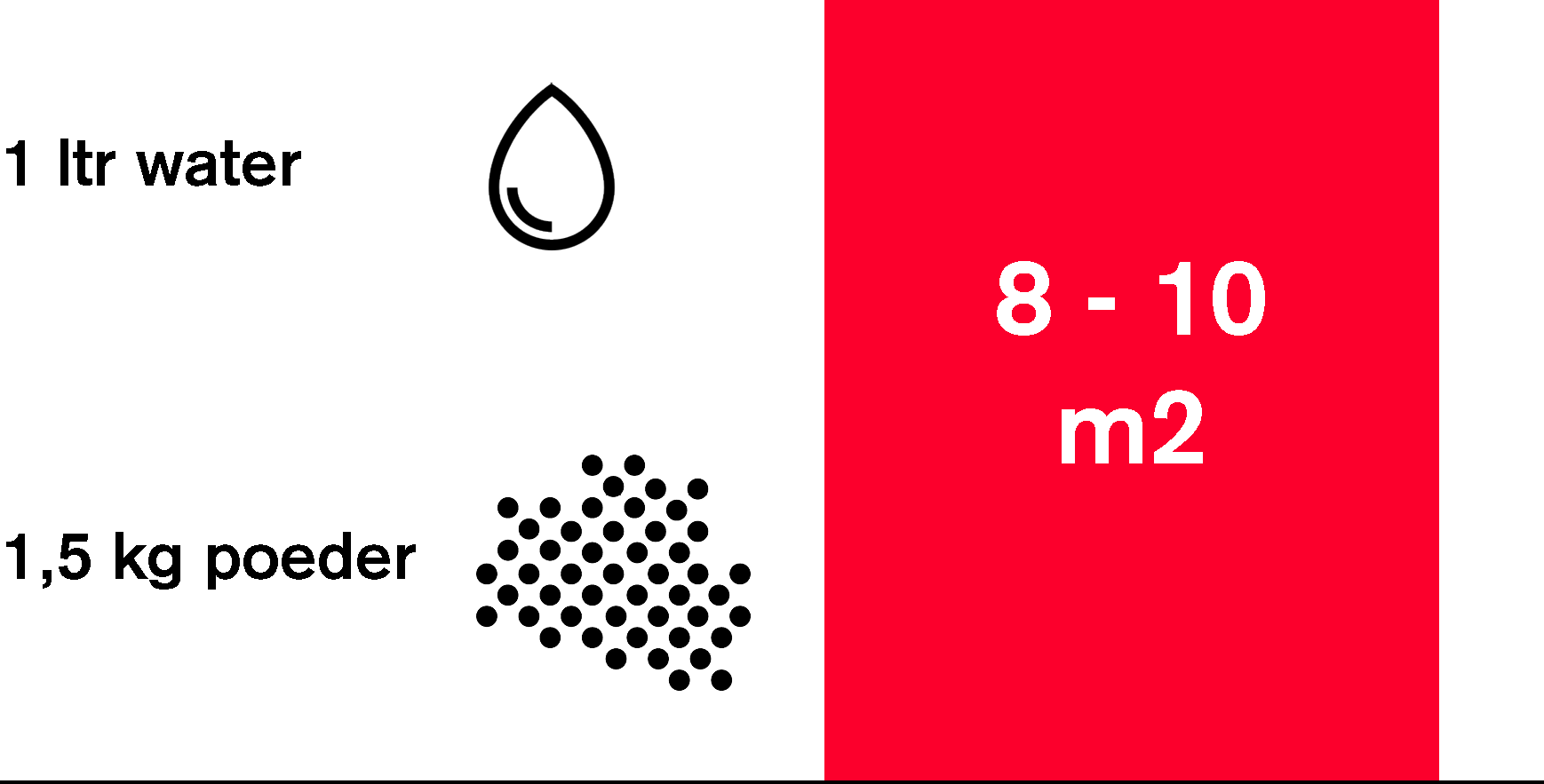

EFFICIENCY 8-10 m2 per liter

SHELF LIFE In closed packaging in a cool and dry place – unmade

PACKAGING UNITS 1 KG bags CONTRETE and 1.5 litre bags of liquid PLUS

Easily stackable and transportable in various sizes of shipping boxes

Paint according to advice and/or standard processing requirements

Suffering from rising damp in the basement?

Do you have salt blooms in the basement?

Let an expert see and fix the cause of the problems. Use BASEPAINT for the right finish!

It can emerge from the building elements used in the basement. Also, the salt blooms can occur as a result of salts ending up in the rising moisture from the ascending walls.

Ask an expert for advice and assess the steps to take before BASEPAINT is applied!

*Make sure you take the right precautions before applying BASEPAINT

- BASEPAINT is a two-component paint system and applicable in cellars. It’s resistant to fluctuating humidity.

- Excellent adhesion on damp surfaces

Suitable on stone and concrete, stucco, masonry and plaster (on a cement base) - Adhesion on damp surfaces higher than 4% moist!

Use the following scheme for creating BASEPAINT

Instructions

Add 1.5KG of BASEPAINT to 1 litre of water in a bucket and mix machine (with

drilling) into a smooth mixture

Ratio

1.5 KG OF BASEPAINT : 1 LITRE OF WATER

PROCESSING TIME

Since it is a fresh product, created paint must be made within 1.5 hours

applied

Processing

Block brush and roller

PROCESSING TEMPERATURE

Not below 5C and above 25C

PRE-TREATMENT

Pre-clean and dust-free surface – do not use primer for

Adhesion

Use a block brush to apply the paint.

We do not recommend using rollers.

For spraying BASEPAINT, please seek advice in advance.

- a bucket

- a mixer (i.c.m. drill)

- a block brush

Use the following scheme for creating BASEPAINT

Instructions

Add 1.5KG OF BASEPAINT to 1 litre of WATER in a bucket and mix machine

with drill to a smooth mixture

Ratio

1.5 KG OF BASEPAINT : 1 LITRE OF WATER

PROCESSING TIME

Since it is a fresh product, created paint must be made within 1.5 hours

applied

Processing

Block brush and roller

PROCESSING TEMPERATURE

Not below 5C and above 25C

PRE-TREATMENT

Pre-clean and dust-free surface – do not use primer for

Adhesion

Use a block brush to apply the paint.

We do not recommend using rollers.

For spraying BASEPAINT, please seek advice in advance.

Extend maintenance period

Due to the excellent adhesion, painting with RAW paints’ products ensures a longer period without maintenance.

Increase UV resistance

Because our paint is easily sprayable – it does not lose the UV reflection.

Efficient in use

Mix what you need! No half-empty cans that are no longer used. The paint is applicable directly to stone surfaces, stucco and concrete (if clean and algae-free) without pre-treatment of primers.

Healthy choice

The paint does not contain preservatives and solvents and is therefore much healthier for painters to work with.

Live consciously

The paint meets some important quality labels (such as anti-allergy, etc.), some still pending.

The step towards sustainability

No water is involved in the production and transport of RAW Paints: this contributes to the CO2 reduction.

Sustainable Development Goals

RAW Paints contributes to 9 out of 17 SDGs.

client: consumer

problems: rising damp – high humidity – musty

client: consumer

problems: